top of page

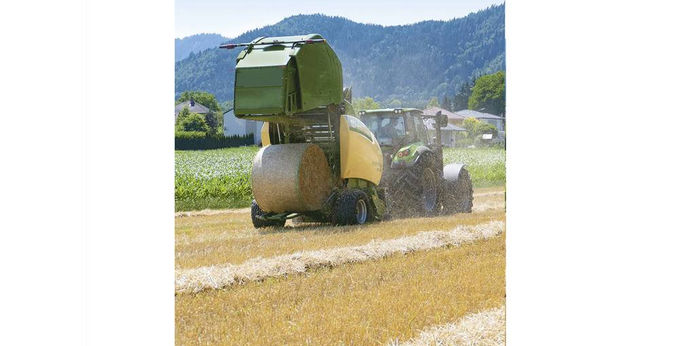

2025 Krone Comprima CF 155 XC

OVERVIEW

Availability: Brochure

Year: 2025

Make:Krone

Model:Comprima CF 155 XC

PRODUCT DESCRIPTION

Comprima was developed by KRONE as a machine that delivers long-term and enduring operation in the most difficult conditions.

Comprima – Round balers and combination baler wrappers

• Developed by KRONE for long-term and enduring operation in the most difficult conditions

• Three chamber systems: fixed, semi-variable, and variable

• Camless EasyFlow pick-up with w-lined tines: for clean rakes and low wear on the tines

• Cut-and-feed rotor: 530 mm diameter for maximum throughputs

• Precision cutting system: for smooth and precision cuts

• NovoGrip system: guarantees effective bale roll and compression in any type of crop

• Straightforward design and servicing for minimum maintenance

Comprima with fixed chamber

• Round baler – Comprima F 125

• Round baler with cutting system – Comprima F 125 XC

• Meeting user demands – 1.25 m diameter bales

• Reliable and simple – clutter-free build, enormous stability

• Sharp – XCut cutting system

Comprima with semi-variable bale chamber

• Round baler – Comprima F 155 (XC)

• Baler wrapper – Comprima CF 155 XC

• Flexible – choice of six bale sizes and 1.25–1.50 m diameters

• Affordable – simple design

• Sharp – XCut cutting system

Comprima with variable bale chamber

• Round balers – Comprima V 150 XC and V 180 XC

• Baler wrapper – Comprima CV 150 XC

• Variable – producing 1.00–1.80 m diameter bales infinitely variably

• Cost-effective – simple and uncluttered design

• Sharp – XCut cutting system

KRONE bale chambers – fixed, semi-variable, or variable

• Matching – the bale chamber which matches the customer's requirements

• Fixed chamber – 1.25 m diameter bales

• Semi-variable – six different bale diameters from 1.25 m to 1.50 m

• Variable – producing infinitely variable 1.00–1.50 m diameters or 1.80 m diameters

Hitch options and running gears

• Variable – hitch ring or ball attachment

• More options – single or tandem axle

• Three options – tyre sizes

KRONE EasyFlow pick-up

• Safe – 6 mm thick double tines with large diameter coils

• Well-balanced – rows of tines arranged in wave shape clear the field evenly

• Clean – extra-wide pick-up drum clears the crops off the field completely

• Simple and effective – no cam track means fewer moving parts, less service and maintenance, extremely quiet running

KRONE feed rotor / XCut cutting unit

• Efficient – large diameter

• Quiet running – helical tine rows

• Continuous flow – for a consistent crop feed

• Sharp – best cutting quality

KRONE NovoGrip slat and belt conveyor

• Sturdy – heavy-duty design

• Maximum pressures – top bale densities

• Smooth – more even and less noisy

• Light and easy – for low input power

• Saving time – no servicing required

KRONE tying unit

• Variable – for net and base coat of film wrapping

• Safe – short distance of the wrapping material to the bale

• Free view – operator has an unimpeded view of the baling process

• Comfortable – automatic start of tying

KRONE wrapping device

• Variable – for net and base coat of film wrapping

• Safe – short distance of the wrapping material to the bale

• Free view – operator has an unimpeded view of the baling process

• Comfortable – automatic start of tying

KRONE easy servicing

• Efficient – best accessibility for easy maintenance

• Automatic lubrication – one lubricator attends to all chains

• Time-saving – central lubrication manifolds

• Safe – automatic chain tension

KRONE operator terminals

• Take your choice – control units suit all needs

• Convenient – clear and user-friendly interfaces

• ISOBUS compatible – connecting with the tractor terminal

• Trend-setting – optimised operation

TIM (Tractor Implement Management)

• Makes operation faster and more comfortable

• Some tractor functions controlled via on-board electronics

• Once bale reaches desired size, TIM stops tractor, starts tying process, opens/closes tailgate

Specifications

• Type: Combination baler and wrappers

• Bale size (m, Ø x width): 1.25–1.50 x 1.20

• Bale chamber: Semi-variable

• Machine dimensions (m, L x W x H): 6.57 x 2.96 x 3.41

• Net wrapping: Standard

• Film wrapping: Optional

• Pick-up working width (m): 2.15

• Power requirement (kW/hp): 74 / 100

• XCut cutting rotor 17 blades, shortest cutting length (mm): 64

• XCut cutting rotor 26 blades, shortest cutting length (mm): 42

bottom of page